Rock Mechanics Laboratory

The Rock mechanics Laboratory was established in the Earth Sciences Department in December 2010 and it is managed by Prof. Bob Holdsworth, Prof. Nicola De Paola, Prof. Stefan Nielsen and Fadul Dawood (Experimental Officer in Rock Mechanics).

It is a cutting-edge facility dedicated to the analysis and testing of rock materials and their mechanical properties. This laboratory is designed to support a wide range of research and practical applications in geology and Earth sciences.

Main facilities include:

Low to High Velocity Rotary Shear Apparatus (LHVR)

The LHVR apparatus can measure the evolution of the frictional properties of both granular and solid rock materials at normal stresses up to 20 MPa and slip rates ranging from 1 mm/year to 1 m/s. By covering this range of velocities, the apparatus allows the laboratory investigation of poorly understood deformation processes occurring along active faults, including both creeping movements and seismic slip.

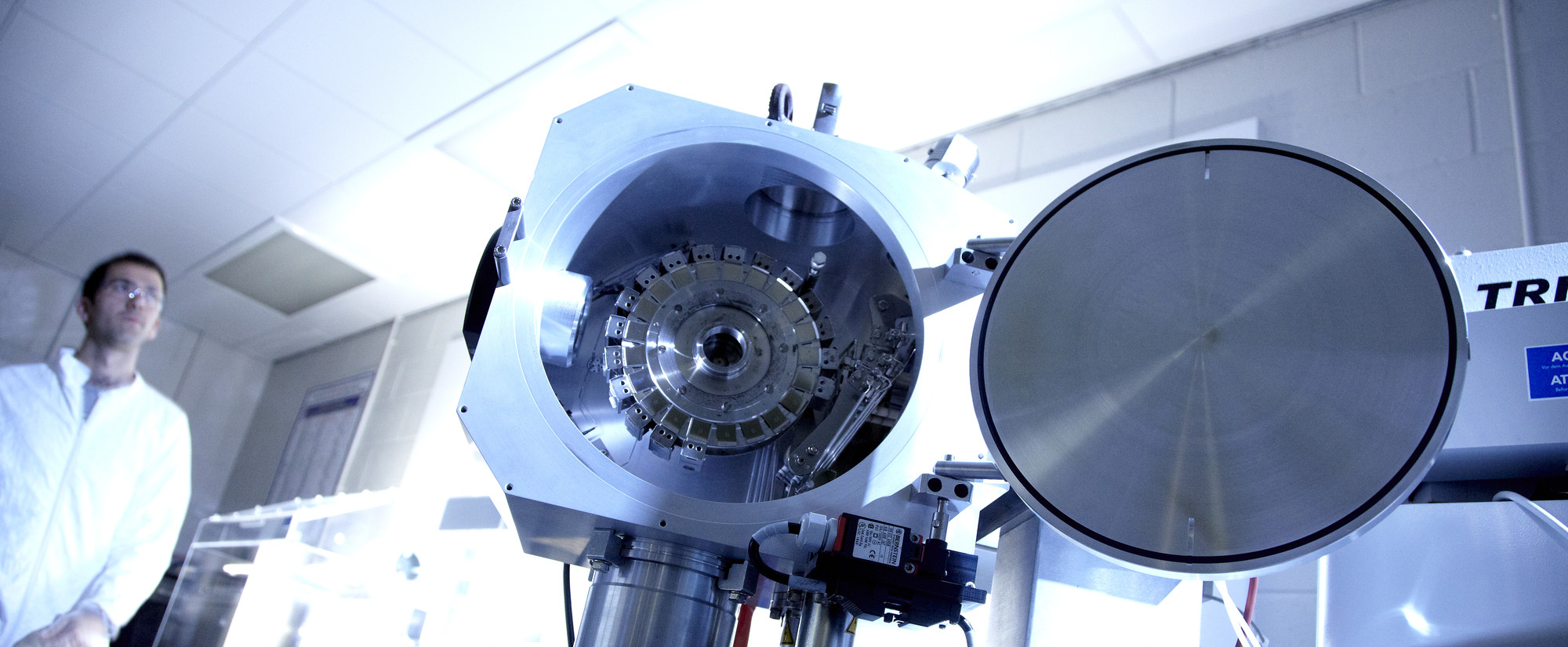

Triaxial Loading Apparatus with Fluid Flow (TFF)

The TFF apparatus allows the quantitative investigation of the fracturing processes of rocks during deformation under upper crustal pressure and temperature conditions (up to 10 km depth), and how these processes can affect the evolution of the rock's fluid transport properties. It also allows the quantitative estimation of the transport properties of rocks (both intact and granular) under evolving conditions of pore fluid pressure and in the presence of reactive fluids (e.g., carbon dioxide).

Biaxial Loading Apparatus with High-Speed Recording Camera

This apparatus allows for the biaxial loading of rock samples and analogue materials while capturing high-speed footage (up to 200000 frames per second) of the deformation and failure processes. The integration of high-speed imaging enables detailed analysis of crack propagation and fracture mechanics. Extensively used in studying the dynamics of rock failure, the high-speed camera captures real-time data on crack initiation and propagation, providing insights into failure mechanisms in natural and analogue materials.

High-Speed Acoustic Emission Acquisition System (Richter)

The high-speed (10 MHz) Richter system is used in tandem with all other apparatus to capture acoustic emissions (AE) generated by the fracturing and deformation of rock samples. The AE system can acquire up to 24 channels in continuous mode for up to a few hours, or in triggered mode for acquiring the rupture events. A strain-gage conditioner/amplifier is also integrated, so that both piezo-electric sensors and strain gages can be monitored by the AE system.

Rock cutting and preparation

The Rock Mechanics Laboratory also contains extensive facilities for rock preparation, including a core drill, cylindrical grinder, and rock crushing tools. More information can be found here.

Facilities and Equipment

Research equipment facilities located in the department

/prod01/prodbucket01/media/durham-university/departments-/earth-sciences/60228-1998X749.jpg)