Research Impact

Our research partnerships have achieved great things with a number of outside companies. The seven examples below were entered into the REF 2022 exercise and 86% was rated as internationally excellent or world leading.

Kromek Group

High Field Metrology for ITER

Durham Magneto Optics

Bruker

CASTEP

P&G – Durham Physics Partnership

Peratech

Kromek Group plc: Materials research underpinning the Stock Market flotation of a radiation detection company

Research in Physics at Durham on vapour growth of II-VI semiconductors developed a technique to grow large crystals of cadmium zinc telluride (CZT), for sensitive X- and gamma-ray detectors. This led to a Physics spin-out company, Kromek Ltd that developed these into full systems for security and medical applications.

Research in Physics at Durham on vapour growth of II-VI semiconductors developed a technique to grow large crystals of cadmium zinc telluride (CZT), for sensitive X- and gamma-ray detectors. This led to a Physics spin-out company, Kromek Ltd that developed these into full systems for security and medical applications.

Customers for Kromek’s radiation detectors includes UK and US governments. Kromek has delivered over 10,000 units of its hand-held D3S radiation detectors that enable dynamic networks of centrally monitored distributed measurements.

In medical imaging, Kromek has massively expanded sales of CZT detectors for bone mineral densitometry, with the unique feature of CZT detectors being a sensitivity to X-ray energy allows bone density and porosity to be independently determined.

Find out more:

Peratech Holdco Ltd: Unique pressure sensitive materials for use in tactile interfaces

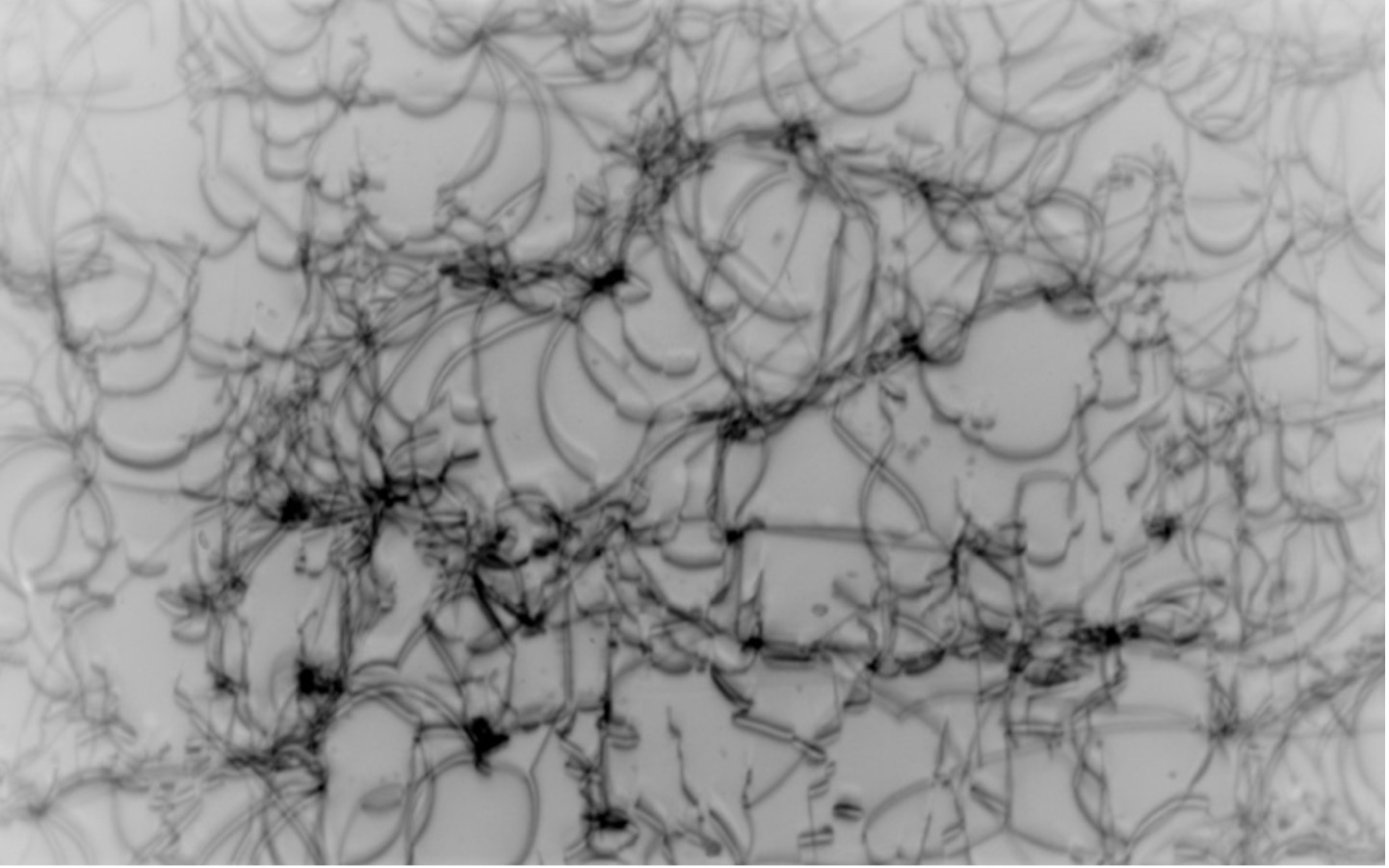

Research in Physics at Durham showed that quantum tunnelling was the physical origin of the unique pressure sensitive behaviour of Peratech’s QTC® (Quantum Tunnelling Composite). More recently, Durham has researched the structure and function of screen-printable, pressure-sensitive inks and Peratech’s QTC® ink-based technology has been integrated into over one million devices.

Research in Physics at Durham showed that quantum tunnelling was the physical origin of the unique pressure sensitive behaviour of Peratech’s QTC® (Quantum Tunnelling Composite). More recently, Durham has researched the structure and function of screen-printable, pressure-sensitive inks and Peratech’s QTC® ink-based technology has been integrated into over one million devices.

Jon Stark, CEO says ‘Peratech is in this position in part due to our long-running research collaboration with Durham University that helped the company fundamentally understand how its QTC materials worked so that it could apply the technology to commercial applications’.

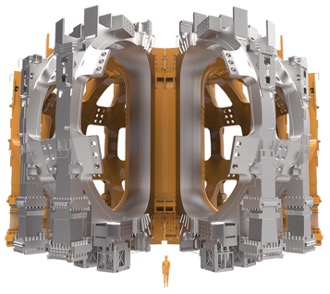

ITER Tokamak: High Field Metrology for the ITER Superconducting Magnets

The ITER tokomak in southern France is a collaboration between 35 nations designed to demonstrate the feasibility of large-scale fusion energy generation. It depends critically on superconducting materials to carry the large currents that enable magnetic confinement of the plasma.

Research in Physics in new instrumentation and measurement protocols were developed to study the current carrying capacity of superconductors and these new methods were applied to the ITER superconductors under stringent operational conditions. The Head of ITER Magnet Group has said that “Durham developed accurate techniques to accurately control temperature and strain and for the first time parameterise the full ITER operational space”, which has impacted on the design, the quality assurance/reliability and construction processes for ITER.

Durham Magneto Optics Ltd: A spin-out company from thin film magnetism research

Research in Durham on laser-based magnetometry for nanomagnetism and spintronics led to the spin-out of Durham Magneto Optics, an export-led, scientific instruments company for nanotechnology R&D. Its magneto-optics technology remains in steady demand world-wide, but it is in a novel laser-based enabling technology, namely direct writing of patterned microstructures, that is responsible for the greatest growth since 2014, increasing the company’s revenue, cash resource, workforce and global reach substantially in the last 4 years.

Research in Durham on laser-based magnetometry for nanomagnetism and spintronics led to the spin-out of Durham Magneto Optics, an export-led, scientific instruments company for nanotechnology R&D. Its magneto-optics technology remains in steady demand world-wide, but it is in a novel laser-based enabling technology, namely direct writing of patterned microstructures, that is responsible for the greatest growth since 2014, increasing the company’s revenue, cash resource, workforce and global reach substantially in the last 4 years.

This device, originally developed in research at Durham, now has world-wide impact in flexible and rapid lithography for electronics device development and as a new low production cost method for microfluidics systems fabrication in the life sciences.

Bruker: A fully automated X-ray tool for in-line defect metrology during semiconductor manufacture

Semiconductor wafers are subject to damage from misaligned handling tools, leading to cracks. Most of these are benign, but a few propagate to cause silicon wafer breakage during high temperature processing, leading to losses in production time costing millions of dollars per year. Research in Durham showed that X-Ray Diffraction Imaging can be used to identify which cracks will fail catastrophically. As a consequence of this research, Jordan Valley UK Ltd, now a division of Bruker, designed and is selling multi-million pounds-worth of X-ray imaging tools into the semiconductor industry, turning what was a specialist laboratory technique into an in-line industrial metrology capability.

CASTEP: A materials modelling code with industrial and academic applications

Research in Physics focused on the development of computation methods to calculate the electronic, physical and chemical properties of materials from first principles has been developed and incorporated in the widely used CASTEP code, which has had worldwide impact beyond academia.

CASTEP is used in a variety of fields, from understanding semiconductor devices and light emitting displays to areas as diverse as the behaviour of Earth minerals, catalysis and drug design. CASTEP was commercialised for use under license by Biovia Inc. and has been purchased by approximately 1,000 high-tech companies developing new materials across chemical, pharmaceutical, auto and jet engine industries.

P&G – Durham Physics Partnership

A unique partnership between Durham University and Procter and Gamble (P&G) has enabled multiple industrially relevant research projects across experimental, computational and theoretical physics. The research underpinning the partnership with P&G spans multiple research disciplines within Physics, including Materials Physics, Advanced Instrumentation, and Computational Cosmology.

A unique partnership between Durham University and Procter and Gamble (P&G) has enabled multiple industrially relevant research projects across experimental, computational and theoretical physics. The research underpinning the partnership with P&G spans multiple research disciplines within Physics, including Materials Physics, Advanced Instrumentation, and Computational Cosmology.

This research has led to new formulations and manufacturing processes for laundry detergents, the design of new liquid-repellent surfaces and improved testing of laundry and dishwasher products, which have been exploited in P&G product lines such as “Tide”, “Ariel”, “Cascade” and “Fairy”.

/prod01/prodbucket01/media/durham-university/departments-/physics/teaching-labs/VT2A9034-1998X733.jpeg)

/prod01/prodbucket01/media/durham-university/departments-/physics/research/impact-case-studies/manwithphone-224X333.jpg)

/prod01/prodbucket01/media/durham-university/departments-/physics/research/impact-case-studies/Tokamak.jpg)

/prod01/prodbucket01/media/durham-university/departments-/physics/research/impact-case-studies/MagnetoOptics.jpg)

/prod01/prodbucket01/media/durham-university/departments-/physics/research/impact-case-studies/Bruker.jpg)

/prod01/prodbucket01/media/durham-university/external-location-photography-/campus-shots-/77881-930X540.jpg)

/prod01/prodbucket01/media/durham-university/departments-/physics/research/impact-case-studies/PG.png)

/prod01/prodbucket01/media/durham-university/departments-/physics/research/impact-case-studies/peratech.jpg)