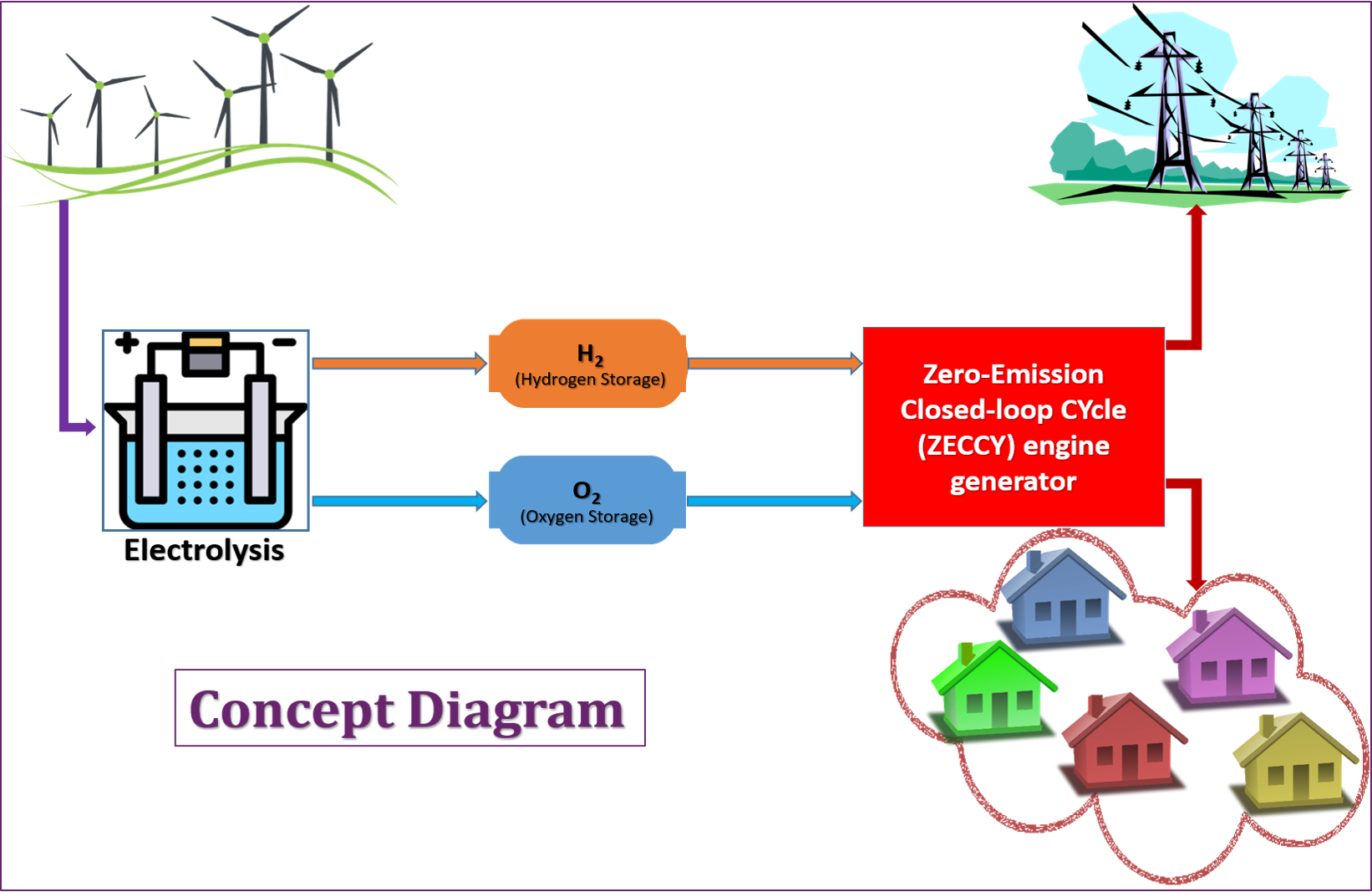

A Zero-Emission Closed-loop linear-Joule CYcle (ZECCY) CHP system

The research team at Durham University are developing a disruptive zero emission, high efficiency combined heat and power ( system that uses stored hydrogen and oxygen from an integrated electrolysis system.

The Zero Emission Closed Cycle ( engine at the heart of the CHP system will not produce any harmful particulates or gas phase GHG emissions - just water.

As such, it is analogous to hydrogen-fuel cell technology but offering a higher electrical efficiency in the 10-1000kWe electrical power range. The other potential advantages of the concept are:

- greater robustness,

- reduced manufacturing cost,

- higher power to weight and power to volume ratios.

The concept uses a new thermodynamic cycle which unlocks a new-paradigm in electrical power generation efficiency (ηe=50%-65%) and the potential to achieve a high total heat and electrical efficiency (ηTotal>90%) for the CHP system.

DEI Team

Aims & Objectives:

The research team at Durham University is the first to establish an advanced design, realisation and demonstration of this concept by designing and testing the 25kWe prototype ZECCY CHP system including a linear generator, condenser, reactor, compressor and expander units.

Furtehr research will boost power-density and energy conversion efficiency through the development and integration of a high-speed, high-efficiency linear (rotary screw) generator. Further development of the design will take place through an extensive test program exploring the design and characterisation of each of its key system components.

This project will demonstrate the true potential of this technology for vehicle applications by:

- Completing the manufacture, assembly and commissioning of a concept demonstrator through the development of an existing test platform.

- Gather the evidence required to advance the project successfully by conducting a robust testing programme underpinned by rigorous simulation and performance improvement.

- Establish the future case of ZECCY generator technology through the development of a technical and commercial roadmap to deployment.

Technical Methodology

- A compressor and expander is created by a double-acting piston cylinder assembly integrated with a linear energy generator.

- In-order to create a synthetic atmosphere, argon and oxygen are mixed and compressed.

- The combustion of hydrogen occurs in an external reactor.

- The combustion produces argon and water vapour which is expanded to drive the linear generator and compressor.

- The exhaust gas after exiting the expander is then cooled in a condenser.

- Water vapour is condensed and exits the cycle. Argon is re-circulated to complete the cycle.

A working fluid better than air: The utilisation of argon and oxygen for the combustion of hydrogen instead of air removes nitrogen from the process and increases the overall efficiency of the linear-Joule cycle over a range of pressure ratios (PR) as shown. The relative differences between the ratio of specific heats for nitrogen (γ=1.3) and argon (γ=1.6) results in an efficiency improvement of approximately 11% across the pressure ratios shown. With a high temperature combustion (>1000K) in the presence of nitrogen in air would result in high levels of harmful NOx formation. Using argon prevents this problem.

Going below atmospheric pressure to boost the pressure ratio: There are practical material properties that limit maximum system pressure and temperature thus limiting the PR. Since this closed-loop system is not coupled to atmospheric conditions on the low-pressure side, the research will explore novel efficiency boosting opportunities by operating at sub-atmospheric pressure and achieving a PR above 50:1. As shown, this would further boost the ideal efficiency by 24%.

Benefits and Impact

- Wind energy can be used to produce hydrogen and oxygen through electrolysis.

- Storage of hydrogen and oxygen allows electricity to be generated which offsets curtailment and wind intermittency issues.

- ZECCY system can be used for power generation or CHP depending on proximity of heat demand.

- Opportunity to have high round trip efficiency because of the increased electrical and thermal efficiency of the CHP system.

- Zero emissions from the reaction of hydrogen and oxygen in the combustion process.

- No scarce materials, complex manufacturing processes or recycling issues.

- Robust, compact and lightweight design.

- Low capital and operational costs.

- Many advantages over using fuel cell technology to recover stored energy vectors – hydrogen and oxygen.

/prod01/prodbucket01/media/durham-university/research-/research-institutes/durham-energy-institute/landscapes-cityscapes-montages-etc/Walney-sunset-2000X800.jpg)